Precision stamping parts are strip-shaped or plate-shaped materials. Under the force of stamping equipment, they are molded by stamping dies to form workpieces of desired shape and size. Stamping parts are widely used, ranging from household equipment to aerospace, and metal stamping parts are inseparable. There are three main elements in the processing of stamping parts, which are raw materials, molds and equipment.

In the processing of stamping parts, the material is required to have higher plasticity and toughness, lower yield ratio and aging sensitivity; generally, the elongation of carbon steel σ≥16%, the yield ratio σs/σb≤70%, Low-alloy high-strength steel σ≥14%, σs/σb≤80%, otherwise, the stamping performance will be relatively poor;

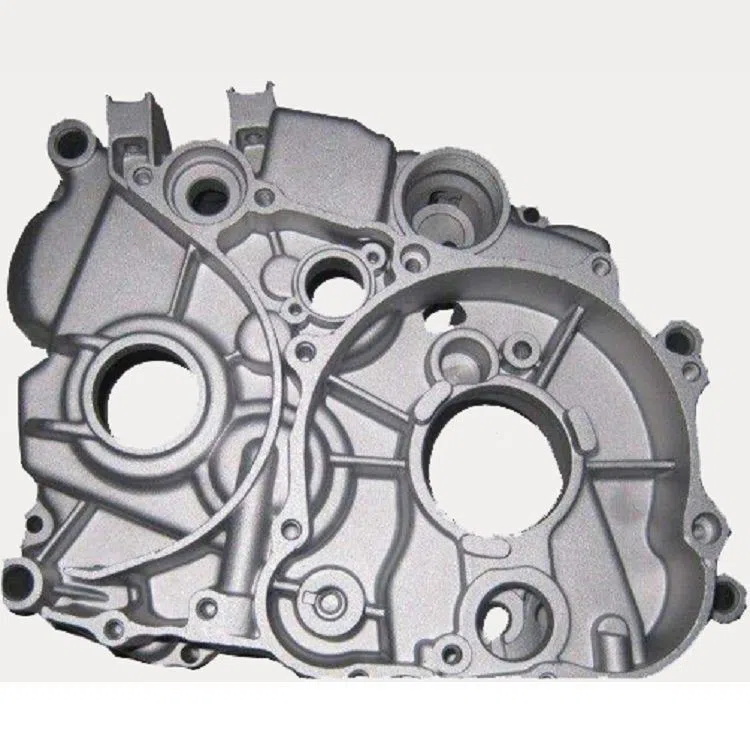

Die is an important equipment for stamping parts processing. The size and accuracy of the mold determine the size and accuracy of the stamping parts. The surface quality of stamping parts, dimensional tolerances, production efficiency and the economic benefits of stamping parts processing manufacturers are closely related to the mold structure and design;

Stamping processing equipment mainly includes mechanical presses and hydraulic presses. When producing a large number of stamping parts, high-speed presses or multi-station automatic presses should be selected as much as possible. In small batch production, especially in the production of large and thick plate stamping parts, most of them use hydraulic presses.