If a metal stamping processing plant wants to extend the service life of the die, it needs to maintain the stamping die regularly. Thorough repair and maintenance of the mold can ensure the production efficiency and quality of future metal stamping products. So, how should the stamping factory maintain the mold?

1. Clean the mold cavity, oil and waste on the mold surface, and spray anti-rust oil after cleaning;

2. Clean the grease on the guide post, guide sleeve, guide plate, blanking ring and guide rail, and add fresh and clean lubricant;

3. Check the condition of the fastening and positioning components, replace the damaged components, and then tighten them if there are loose parts;

4. Check the drawings, whether the forming and pressing surfaces are worn, and then repair the worn parts by welding, grinding, polishing and other treatments;

5. Check the pressing and unloading parts, and repair and replace damaged parts;

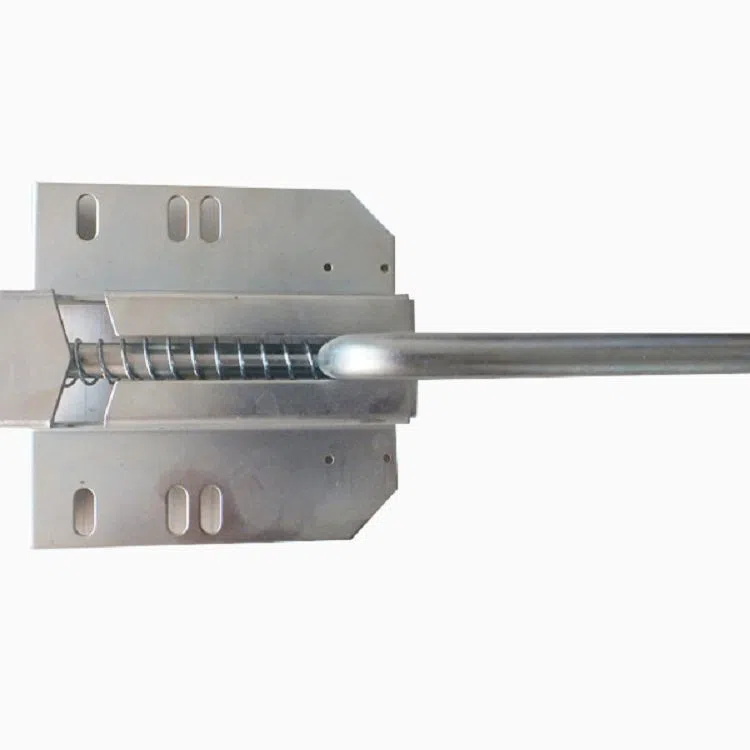

6. Check the guiding device and the inclined wedge device to repair and replace worn and broken parts;

7. Check the wear status of the punch and cutting edge, repair and replace the worn area;

8. Check the template, whether the mold is worn or deformed, whether the parts are worn or deformed, for repair and replacement;

9. Check the gap between the molds and the wear of the ridgeline, if there is wear, maintenance is required.